![]()

|

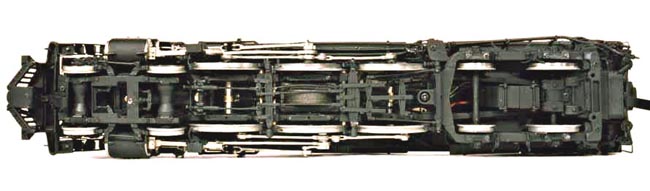

The underside of our locomotive has every detail possible, allowing for operational considerations. All of the drive axles and trailing truck axles will be fully equalized, just as the actual prototypes were. Few builders have gone to the trouble and expense of including these features and many would tell you that it is not necessary. Through complete and thorough testing we have seen the positive results utilizing the model locomotive dynamometer that we have developed for design and testing purposes. This unique new tool has allowed us to fine-tune our design to the point where our pilot sample model is developing approximately three (3) pounds of pulling power utilizing stainless steel drivers on nickel silver rail, this is exceptional for a 4-6-4 wheel arrangement locomotive. As a matter of interest, we have gained almost a full pound of pulling power in this development process. All axles on both the locomotive and tender run in ball-bearings races. The drive mechanism is fully ball-bearing equipped. Unlike other models that use the more typical worm gear drive, our free-coasting design utilizes custom-cut bevel gears for smooth, quiet and reliable operation. All of our components are covered by a limited lifetime warranty to the original owner, so it is to our benefit as well as the customers that our design is thoroughly tested and proven. The model incorporates the latest sound technology from Dallee Electronics. Using dual microprocessors, the model will accurately reproduce the digitally recorded sounds of the cylinder exhaust, bell, whistle, compressors, brake release and safety valves. The sound of the cylinder exhaust is fully synchronized with the valve-gear and drivers of the locomotive using an infra-red sensor. The sound system is fully DCC compatible and also comes with it's own digital controller for those of you that are not using DCC. The sounds of the locomotive emanate from within the boiler where they should. A feature that has never been included in a production model is the electronically controlled valve/reverse gear. We will be including this feature which automatically sets the correct position based on the direction that the locomotive will be traveling before the locomotive starts moving, unlike other models which 'drag' the mechanism into position as they run. Another development first is the availability on an optional basis of or digitally controlled dynamic brake unit. This is a non-friction device that is controlled using it's own control box or by assigning it as a function if you are a DCC operator. The braking unit interacts with the motor and gearbox to control the loco and consist on grades or in emergency situations. This is an option for the operator that wants the ultimate in control, to an extent never before offered. This feature is so unique that it has already earned the attention of Model Railroader magazine. |